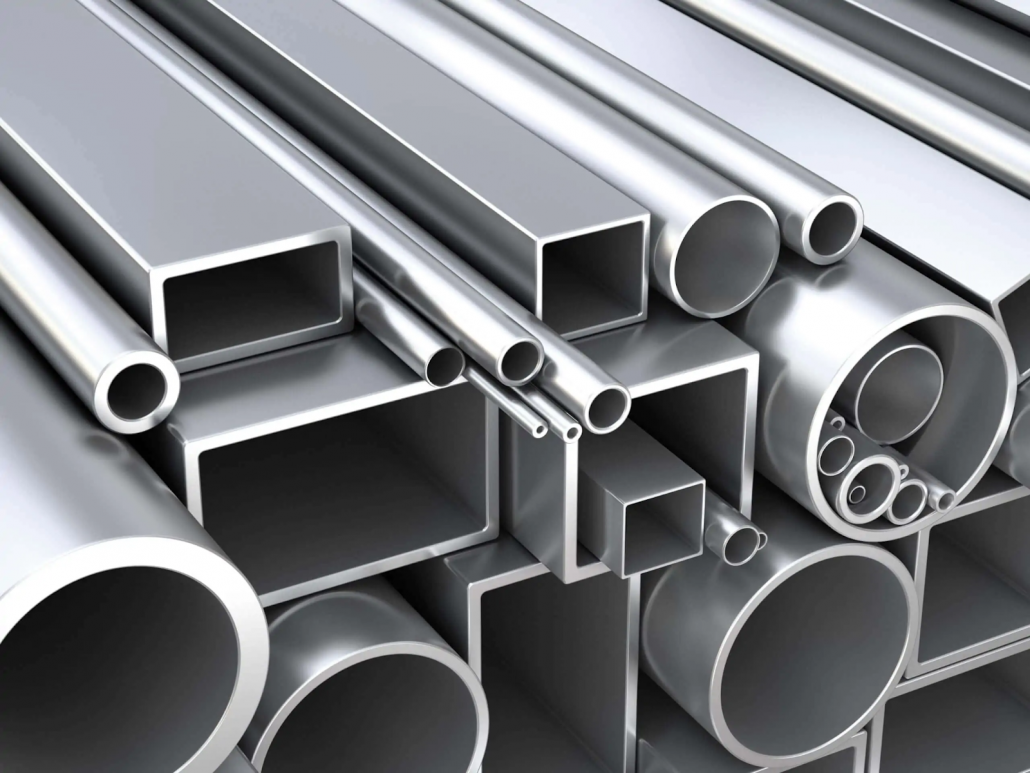

Aluminum vs Cast Aluminum: Understanding the Differences

When it comes to materials used in manufacturing and construction, aluminum and cast aluminum are often mentioned in discussions due to their widespread use and versatile properties. Both materials share a similar base element, but they have distinct differences that impact their application, performance, and manufacturing processes. In this article, we will explore the key […]

Aluminum vs Cast Aluminum: Understanding the Differences Read More »