China has emerged as a global leader in the manufacturing of injection molds, catering to a wide range of industries. From automotive to electronics, Chinese manufacturers are known for their ability to produce high-quality molds at competitive prices. This article delves into the prominent aspects of the injection mold manufacturing industry in China, highlighting the reasons for its global dominance.

1. Injection Mold Manufacturers in China: A Thriving Industry

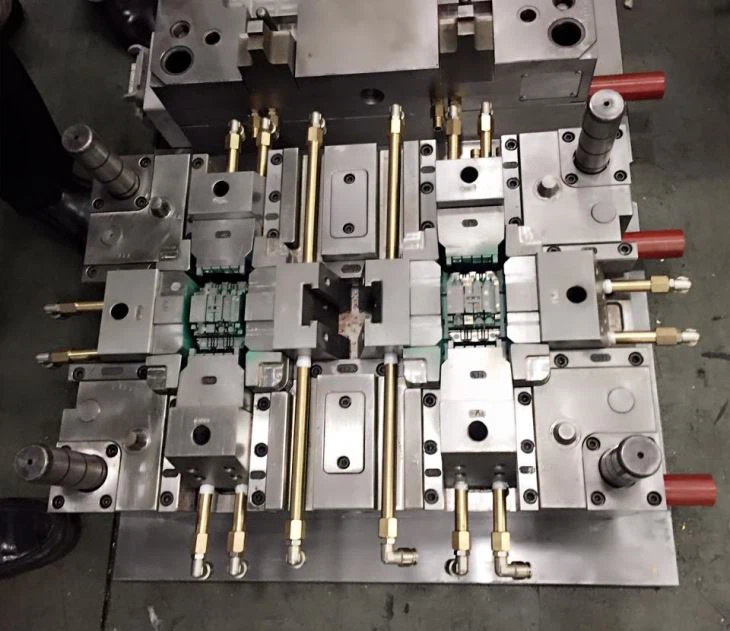

Injection molding has become an essential manufacturing technique for various industries, and China stands out as a hub for this technology. Chinese injection mold manufacturers are celebrated for their ability to produce molds with precision and efficiency. This excellence can be attributed to their investment in advanced machinery, skilled workforce, and commitment to quality standards. Many manufacturers utilize cutting-edge technologies such as CNC machining, EDM (Electrical Discharge Machining), and automated assembly lines to ensure the molds meet global quality requirements. Moreover, the cost-effectiveness of producing injection molds in China is a significant advantage. With a competitive labor market and efficient production processes, Chinese manufacturers provide value for money, making them the go-to option for businesses worldwide.

2. Top Mold Manufacturers in China: Setting Global Standards

When searching for mold manufacturers in China, businesses often prioritize quality, reliability, and on-time delivery. Leading manufacturers in the country adhere to international standards like ISO9001, ensuring that their products meet the rigorous demands of global clients. They cater to diverse industries, including automotive, consumer electronics, medical devices, and packaging. Key players in the Chinese mold manufacturing industry also focus on customization. They work closely with clients to design and produce molds tailored to specific needs, ensuring that the finished product aligns perfectly with the client’s requirements. These manufacturers also emphasize after-sales support, providing repair services, maintenance, and technical assistance to ensure customer satisfaction.

3. Why China Mold Manufacturers Dominate the Market

Several factors contribute to the success of Chinese mold manufacturers. Firstly, China boasts a vast industrial ecosystem, enabling manufacturers to source raw materials and components at competitive prices. Additionally, the country’s strong focus on research and development (R&D) ensures continuous improvement in mold-making technologies. Chinese manufacturers are also known for their flexibility and ability to handle both large-scale and small-batch orders. Whether a client needs thousands of molds for mass production or a limited number for specialized applications, Chinese mold makers can deliver with equal efficiency. Their expertise in producing molds for complex designs, tight tolerances, and challenging materials further enhances their appeal to global clients.

4. Mold Manufacturers in China: Driving Innovation

Innovation is at the core of the mold manufacturing industry in China. Many manufacturers are investing heavily in R&D to stay ahead of the curve. They are adopting technologies such as 3D printing, which allows for rapid prototyping and reduces the time required to develop and test new mold designs. This innovation enables Chinese mold manufacturers to provide faster lead times without compromising quality. Additionally, automation is playing a significant role in improving efficiency and consistency in mold production. Robotic systems and AI-powered quality control mechanisms are being employed to minimize errors and enhance productivity. By embracing these technologies, Chinese manufacturers are setting benchmarks for the global mold-making industry.

5. Plastic Mold Manufacturers in China: Catering to Diverse Needs

Plastic mold manufacturing is a significant segment of the mold industry in China. These manufacturers specialize in creating molds for producing plastic parts used in various applications, such as automotive interiors, medical devices, packaging, and consumer electronics. The versatility of plastic as a material makes it a popular choice for manufacturers, and Chinese mold makers excel in designing molds for complex plastic components. Chinese plastic mold manufacturers often use high-grade materials like P20 steel, stainless steel, and aluminum to ensure durability and performance. They also offer services like mold flow analysis, which helps optimize the design and minimize defects in the molded parts. This comprehensive approach ensures that clients receive high-quality molds that meet their exact specifications.

6. Key Considerations When Choosing a Mold Manufacturer in China

For businesses looking to partner with a mold manufacturer in China, several factors should be considered:

- Experience and Expertise: Choose manufacturers with a proven track record in producing molds for your specific industry.

- Quality Assurance: Look for certifications like ISO9001 and inquire about their quality control processes.

- Customization Options: Ensure the manufacturer can customize molds to suit your requirements.

- Lead Time: Confirm their ability to deliver molds within the required timeframe.

- After-Sales Support: Opt for manufacturers who offer comprehensive after-sales services, including repairs and maintenance.

By keeping these considerations in mind, businesses can identify reliable partners in China’s mold manufacturing sector.

7. Future Prospects of the Mold Manufacturing Industry in China

The future of mold manufacturing in China looks promising, with the industry poised for further growth. Advances in materials science and manufacturing technologies are expected to drive innovation in mold design and production. Furthermore, the increasing adoption of sustainable practices, such as the use of eco-friendly materials and energy-efficient processes, will enhance the industry’s appeal to environmentally conscious clients.

China’s Belt and Road Initiative (BRI) is also likely to play a role in expanding the global reach of Chinese mold manufacturers. By improving connectivity and fostering international trade, the BRI will open up new markets for Chinese molds, further solidifying the country’s position as a leader in the industry. China’s mold manufacturing industry has established itself as a global powerhouse, thanks to its commitment to quality, innovation, and customer satisfaction. Whether it’s injection molds or plastic molds, Chinese manufacturers offer unparalleled expertise and value. As the industry continues to evolve, businesses worldwide can rely on China’s mold manufacturers to meet their needs with precision and efficiency.

Exploring the Excellence of Mold Manufacturers in China

China’s position as a leader in mold manufacturing is indisputable. The country has built a reputation for its ability to produce injection molds and plastic molds that meet global industry standards while offering cost-effective solutions. With a thriving industrial ecosystem, a focus on innovation, and a commitment to customer satisfaction, Chinese mold manufacturers have transformed the global supply chain. In this extended exploration, we’ll delve deeper into the factors that make China the premier destination for mold manufacturing and how businesses can capitalize on the expertise of Chinese mold makers.

1. The Versatility of Injection Mold Manufacturers in China

Injection molding is a highly adaptable process, making it indispensable for industries that require precision manufacturing of complex parts. Chinese injection mold manufacturers stand out because they cater to a wide variety of industries, including:

- Automotive: From engine components to interior plastic parts, molds for the automotive sector must meet stringent safety and performance standards. Chinese manufacturers are equipped with advanced technologies that allow them to meet these demands efficiently.

- Medical Devices: The medical industry relies on precision-engineered molds for devices like syringes, surgical tools, and diagnostic equipment. Manufacturers in China understand the importance of tight tolerances and cleanroom production environments for these applications.

- Electronics: The fast-evolving electronics industry requires molds for products ranging from casings to connectors. Chinese mold makers are adept at producing molds for high-tech applications.

What sets Chinese manufacturers apart is their ability to work with a range of materials, including thermoplastics, metals, and even composites. Their ability to scale production to meet both low-volume and mass-production requirements ensures they can support diverse client needs.

2. Key Technologies Powering Mold Manufacturing in China

One of the reasons behind China’s dominance in mold manufacturing is its adoption of state-of-the-art technologies. Chinese manufacturers are investing in cutting-edge equipment and techniques to ensure their products are at the forefront of innovation.

- CNC Machining: This technology allows for the precise creation of molds with complex geometries and tight tolerances. Chinese manufacturers leverage multi-axis CNC machines to deliver high-quality results.

- 3D Printing: Rapid prototyping with 3D printing is becoming a cornerstone of the mold-making process. It reduces development time and allows manufacturers to validate designs before committing to full-scale production.

- Mold Flow Analysis: By simulating the injection molding process, Chinese manufacturers can optimize mold designs to minimize defects such as warping or sink marks. This not only improves product quality but also reduces production costs.

- Automation: Automation has been widely adopted in mold manufacturing facilities across China. Robotic systems are used for processes like polishing, assembly, and quality inspection, ensuring consistency and efficiency.

These technologies enable Chinese mold manufacturers to produce molds that meet the high standards of industries such as aerospace, automotive, and medical devices.

3. Advantages of Choosing Chinese Mold Manufacturers

China’s mold manufacturing industry is characterized by several competitive advantages that make it the preferred choice for businesses worldwide. Some of the key benefits include:

- Cost-Effectiveness: One of the most significant advantages of working with Chinese manufacturers is the ability to access high-quality molds at a fraction of the cost compared to manufacturers in other countries. This is made possible by efficient production methods, lower labor costs, and a well-established supply chain.

- Fast Turnaround Times: With their advanced facilities and skilled workforce, Chinese mold manufacturers can deliver molds quickly, even for large-scale orders. This is particularly important for industries operating on tight production schedules.

- Comprehensive Services: Many Chinese manufacturers offer end-to-end services, including design, prototyping, manufacturing, and after-sales support. This eliminates the need for clients to coordinate with multiple vendors, simplifying the supply chain.

- Global Reach: China’s mold manufacturers have extensive experience working with international clients. They are familiar with export regulations and requirements, ensuring a seamless experience for businesses operating in different regions.

These advantages have made China a hub for businesses seeking reliable and cost-efficient mold manufacturing solutions.

4. Plastic Mold Manufacturing: A Specialty of Chinese Mold Makers

The production of plastic molds is a key area of expertise for Chinese mold manufacturers. Plastic molds are used to create components across a wide range of industries, from everyday consumer goods to specialized industrial parts. Chinese manufacturers are proficient in designing and producing plastic molds for applications such as:

- Packaging: From food containers to bottles, molds for the packaging industry must meet high standards of precision and durability. Chinese mold makers excel in delivering molds that can withstand repeated use without compromising product quality.

- Consumer Products: Household items, toys, and gadgets often rely on plastic molds. Manufacturers in China are skilled at creating molds for aesthetically appealing and functional products.

- Automotive Plastics: Interior trim, dashboard components, and exterior features like bumpers are often produced using plastic molds. Chinese manufacturers are experts at designing molds for automotive applications, ensuring they meet industry-specific requirements.

Plastic mold manufacturers in China use high-grade materials to ensure longevity and performance. They also emphasize sustainability by adopting energy-efficient processes and incorporating recyclable materials where possible.

5. How Chinese Mold Makers Cater to Diverse Industries

One of the defining features of Chinese mold manufacturers is their versatility. They serve a wide range of industries, each with its own unique requirements. Here’s how they meet the needs of different sectors:

- Aerospace and Defense: The aerospace industry demands high-precision molds for components that must withstand extreme conditions. Chinese manufacturers use advanced technologies to produce molds that meet these exacting standards.

- Construction: From fittings to structural components, construction applications require durable and reliable molds. Chinese mold makers deliver products that meet the stringent safety and durability standards of the industry.

- Electronics: With the rise of smart devices, Chinese manufacturers are playing a critical role in producing molds for electronics. These molds must meet tight tolerances and deliver high repeatability for mass production.

The ability to adapt to the unique demands of different industries has cemented China’s position as a global leader in mold manufacturing.

6. Sustainability in Mold Manufacturing: A Growing Trend in China

Sustainability is becoming a critical consideration in the manufacturing industry, and China’s mold manufacturers are no exception. They are taking steps to reduce their environmental footprint by adopting eco-friendly practices, such as:

- Using Sustainable Materials: Many manufacturers are incorporating recyclable and biodegradable materials into their processes.

- Energy Efficiency: By using energy-efficient machinery and optimizing production processes, manufacturers are reducing their energy consumption.

- Waste Reduction: Advanced technologies like 3D printing and automated systems help minimize material waste during mold production.

These practices not only benefit the environment but also enhance the appeal of Chinese mold manufacturers to environmentally conscious clients.

7. Choosing the Right Mold Manufacturer in China: A Guide for Businesses

For businesses looking to partner with a Chinese mold manufacturer, it’s essential to select the right partner. Here are some tips to help you make an informed decision:

- Evaluate Experience: Look for manufacturers with experience in producing molds for your specific industry.

- Check Certifications: Ensure the manufacturer adheres to international quality standards, such as ISO9001.

- Review Past Projects: Ask for case studies or references to assess the manufacturer’s capabilities.

- Assess Communication: Effective communication is critical when working with overseas partners. Choose a manufacturer who is responsive and transparent.

- Visit Facilities: If possible, visit the manufacturer’s facilities to assess their capabilities and quality control processes.

By following these steps, you can identify a reliable and competent mold manufacturer in China.

8. Challenges and Solutions in Working with Chinese Mold Manufacturers

While working with Chinese mold manufacturers offers numerous advantages, there are also challenges that businesses may encounter. These include:

- Language Barriers: Communication issues can arise due to language differences. However, many manufacturers employ English-speaking staff to facilitate smooth interactions.

- Quality Concerns: Some businesses may worry about quality standards. Partnering with reputable manufacturers and conducting regular inspections can help address this concern.

- Shipping Delays: International shipping can sometimes lead to delays. Working with manufacturers experienced in exporting can minimize this risk.

By proactively addressing these challenges, businesses can enjoy a seamless experience when working with Chinese mold manufacturer

The Unparalleled Growth of China’s Mold Manufacturing Industry

China’s mold manufacturing industry has not only established itself as a leader in the global market but also continues to evolve rapidly to meet the increasing demands of modern industries. This growth is fueled by the country’s advanced infrastructure, a strong focus on research and development (R&D), and a culture of innovation that ensures Chinese manufacturers stay competitive. As the industry progresses, the ability to deliver high-quality molds such as injection molds and plastic molds at affordable costs makes China a vital player in global manufacturing.

1. Emerging Trends in Mold Manufacturing in China

As technology evolves, the mold manufacturing industry in China is embracing new trends to stay ahead. Some of the key trends include:

- Digital Transformation: The integration of digital technologies like Artificial Intelligence (AI), Internet of Things (IoT), and cloud computing is revolutionizing the mold production process. These tools improve efficiency, enhance precision, and allow manufacturers to offer predictive maintenance services for molds.

- Sustainability: Many Chinese mold manufacturers are shifting towards greener production methods. This includes reducing carbon footprints, recycling materials, and using energy-efficient equipment.

- Focus on Lightweight Materials: As industries like automotive and aerospace emphasize fuel efficiency, Chinese mold makers are developing molds for lightweight yet durable materials, such as composites and advanced polymers.

By staying in line with these trends, Chinese mold manufacturers continue to adapt to global requirements, offering innovative solutions that cater to emerging needs.

2. How China Supports Small and Medium-Sized Enterprises (SMEs) in Mold Manufacturing

China’s mold manufacturing industry does not just cater to multinational corporations; it also actively supports small and medium-sized enterprises (SMEs). These businesses often have limited budgets but require high-quality molds to remain competitive. Chinese mold manufacturers excel at providing affordable yet top-notch solutions tailored to the needs of SMEs.

- Flexible Production Runs: Chinese manufacturers are equipped to handle both low-volume and high-volume production, allowing SMEs to order molds in quantities that suit their budgets.

- Cost-Effective Prototyping: By leveraging technologies like 3D printing, Chinese manufacturers help SMEs reduce costs during the product development phase.

- Global Reach for Small Businesses: Many Chinese mold makers have experience working with startups and SMEs worldwide, offering them access to high-quality molds without the prohibitive costs typically associated with Western suppliers.

This focus on affordability and customization enables SMEs to compete in their respective markets while maintaining high standards of production.

3. China’s Role in the Automotive Mold Industry

One of the largest sectors driving the demand for molds is the automotive industry. China plays a significant role in supplying molds for automotive components such as bumpers, dashboards, and engine parts. This dominance is supported by the following factors:

- Expertise in Complex Mold Designs: Automotive parts often have intricate designs and tight tolerances. Chinese manufacturers have the capability to produce molds for even the most complex components.

- Use of High-Strength Materials: Molds for automotive applications are subjected to repeated use under high-pressure environments. Chinese mold makers use high-grade materials like hardened steel to ensure the durability and longevity of their molds.

- Support for Electric Vehicles (EVs): With the rise of EVs, there is a growing need for molds to produce lightweight and efficient components. Chinese manufacturers are actively developing molds to cater to this fast-growing segment of the automotive market.

As the global automotive industry evolves, China’s mold manufacturers continue to innovate, ensuring they remain a key partner for leading automakers.

4. Streamlining the Supply Chain with Chinese Mold Makers

One of the main advantages of working with Chinese mold manufacturers is their ability to streamline the supply chain. The efficiency of China’s manufacturing ecosystem allows for seamless collaboration between mold makers and other industries, resulting in faster production cycles and reduced costs.

- Close Proximity to Suppliers: Many Chinese mold manufacturers are located near suppliers of raw materials and components, enabling them to source materials quickly and at competitive prices.

- One-Stop Solutions: Many manufacturers provide end-to-end services, from initial design to the delivery of finished molds, reducing the need for intermediaries and simplifying the supply chain.

- Global Logistics Expertise: With extensive experience in exporting molds, Chinese manufacturers understand the complexities of international logistics and customs, ensuring timely delivery of products to clients worldwide.

These supply chain advantages make China an ideal destination for businesses looking to optimize their manufacturing processes.

5. Quality Assurance and Customer Satisfaction in Chinese Mold Manufacturing

Quality assurance is a cornerstone of China’s mold manufacturing industry. Leading manufacturers invest heavily in quality control systems to ensure that every mold meets stringent standards. Some of the key quality assurance practices include:

- Advanced Inspection Equipment: Many Chinese manufacturers use Coordinate Measuring Machines (CMM), laser scanners, and other advanced tools to inspect molds with extreme precision.

- In-House Testing: Manufacturers often conduct extensive testing of molds before delivery, ensuring they perform reliably under production conditions.

- Customer Feedback and Support: Chinese mold makers emphasize client satisfaction by maintaining open lines of communication throughout the production process. They also provide after-sales support, including maintenance, repairs, and technical assistance.

By prioritizing quality assurance and customer satisfaction, Chinese mold manufacturers build long-term relationships with clients and maintain their reputation in the global market.

6. The Role of Government Support in Advancing Mold Manufacturing

The Chinese government has played a crucial role in the growth of the mold manufacturing industry. By offering subsidies, tax incentives, and funding for research and development, the government has encouraged innovation and modernization in the sector. Initiatives like “Made in China 2025” focus on promoting high-tech manufacturing, further solidifying China’s position as a global leader in mold production.

Additionally, government investment in infrastructure, such as modern industrial parks and export facilities, has facilitated the growth of mold manufacturers. These measures ensure that Chinese mold makers can operate efficiently and compete on a global scale.

7. Why China Will Remain a Global Leader in Mold Manufacturing

China’s mold manufacturing industry is well-positioned to maintain its global leadership for several reasons:

- Strong Workforce: China has a highly skilled workforce, including engineers, designers, and technicians, who are experts in mold manufacturing.

- Commitment to R&D: Continuous investment in research and development ensures that Chinese manufacturers stay at the forefront of mold-making technologies.

- Focus on Customization: The ability to deliver customized molds tailored to specific client needs ensures that Chinese manufacturers remain relevant in diverse industries.

- Competitive Pricing: Despite increasing competition from other regions, China continues to offer some of the most competitive prices in the global market without compromising quality.

These strengths, combined with the country’s robust industrial ecosystem, ensure that China will remain a preferred choice for businesses seeking high-quality molds.

Conclusion

The mold manufacturing industry in China is a testament to the country’s industrial expertise, technological innovation, and commitment to quality. From injection molds to plastic molds, Chinese manufacturers cater to a diverse range of industries with unmatched precision and efficiency. Their ability to combine affordability with advanced technology has made them indispensable partners for businesses worldwide.

As the industry continues to evolve, Chinese mold manufacturers are embracing sustainability, digital transformation, and emerging trends to stay competitive. With strong government support, a skilled workforce, and a focus on customer satisfaction, China’s mold manufacturing industry is set to thrive in the years to come, reinforcing its position as a global leader in the field.