Arizona has emerged as a prominent hub for injection molding companies, catering to various industries such as automotive, medical, aerospace, electronics, and consumer goods. The state’s pro-business environment, access to cutting-edge technology, and skilled workforce make it an attractive destination for companies seeking high-quality plastic manufacturing solutions.

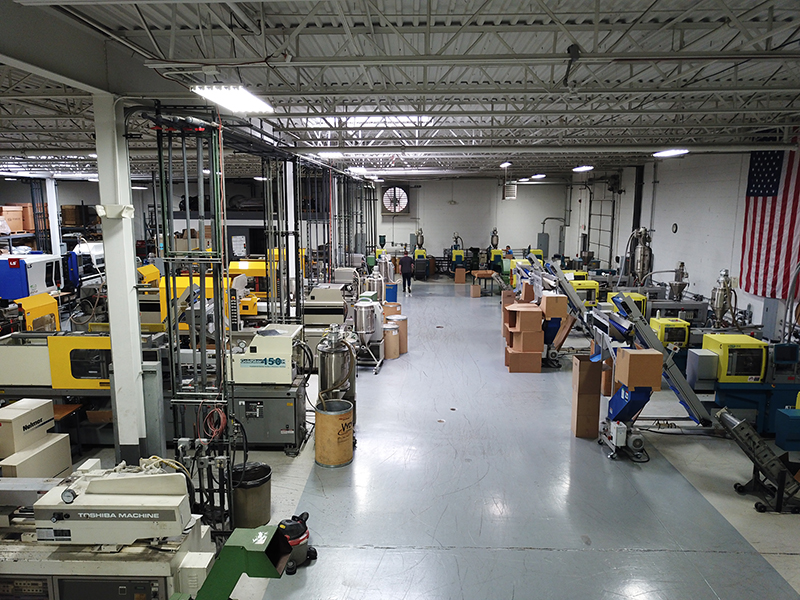

With a growing emphasis on advanced manufacturing, many injection molding companies in Arizona are investing in automation, precision engineering, and sustainable production practices. These factors contribute to the state’s rising reputation as a reliable location for high-performance plastic parts production.

Why Arizona is a Prime Location for Injection Molding Companies

Business-Friendly Environment and Economic Growth

Arizona offers an ideal setting for manufacturers, with business-friendly policies, competitive tax rates, and financial incentives for industrial investments. The state’s robust infrastructure, including access to major transportation routes and ports, supports efficient distribution and supply chain management. This pro-growth environment attracts both domestic and international injection molding companies looking to expand their operations.

Skilled Workforce and Technological Advancements

Arizona boasts a well-trained workforce, with many professionals specializing in plastic injection molding, engineering, and automation. Technical training programs and partnerships between industry leaders and educational institutions help ensure a steady pipeline of skilled workers. Many injection molding companies in Arizona invest in workforce development initiatives to maintain high production standards and meet the demands of modern manufacturing.

The use of state-of-the-art technologies, including robotics, real-time quality control, and data-driven manufacturing, enables Arizona’s injection molding companies to achieve precision, efficiency, and reduced production costs. The integration of smart manufacturing practices ensures consistent product quality and operational excellence.

Sustainability and Eco-Friendly Manufacturing

Environmental responsibility is a key focus for many injection molding companies in Arizona. Manufacturers are increasingly adopting sustainable practices, such as using biodegradable plastics, recycling plastic waste, and improving energy efficiency. These efforts align with global sustainability goals while helping companies reduce material costs and minimize environmental impact.

Industries Served by Injection Molding Companies in Arizona

Automotive Industry

The automotive sector is a major market for Arizona’s injection molding companies. Plastic components play a critical role in vehicle design, offering lightweight, durable, and cost-effective alternatives to metal parts. Injection-molded components such as dashboards, door panels, air vents, and structural reinforcements contribute to improved fuel efficiency and vehicle performance.

Medical and Healthcare Industry

Arizona has a strong presence in the medical device industry, with many injection molding companies specializing in the production of high-quality medical components. These manufacturers adhere to strict industry regulations and certifications, ensuring compliance with FDA and ISO standards. Commonly produced medical injection-molded products include syringes, IV components, implantable devices, and surgical tools.

Aerospace and Defense Industry

Arizona’s aerospace and defense sectors require precision-engineered plastic components that can withstand extreme conditions. Injection molding companies in the state produce parts for aircraft interiors, structural supports, and military equipment. The use of high-performance polymers and composite materials ensures durability, heat resistance, and lightweight solutions for aerospace applications.

Electronics and Consumer Goods

Arizona’s injection molding companies supply plastic components to the consumer goods and electronics industries. From smartphone casings to household appliances, injection-molded parts enhance product functionality and design. Advanced manufacturing techniques allow for intricate detailing and high-volume production, making Arizona-based manufacturers a reliable choice for electronic and consumer product companies.

Custom Injection Molding Services in Arizona

Prototype Development and Rapid Tooling

Many injection molding companies in Arizona offer custom molding services, including prototype development and rapid tooling. These services allow businesses to test and refine product designs before committing to full-scale production. Rapid prototyping helps manufacturers minimize design flaws and optimize product performance.

Material Selection for Specific Applications

Selecting the right material is crucial for achieving the desired properties in an injection-molded part. Arizona-based manufacturers offer a wide range of plastic resins, including thermoplastics, high-temperature polymers, and specialty materials. Companies work closely with clients to determine the best material for each application, ensuring durability, flexibility, and cost efficiency.

Overmolding and Secondary Operations

Many injection molding companies in Arizona provide additional services such as overmolding, assembly, and finishing. Overmolding involves molding a second material over an existing plastic part, enhancing grip, comfort, or functionality. Secondary operations, including painting, ultrasonic welding, and custom labeling, allow businesses to receive fully finished products ready for market.

Challenges Facing Injection Molding Companies in Arizona

Fluctuating Material Costs and Supply Chain Issues

Like other manufacturing industries, injection molding companies in Arizona face challenges related to fluctuating raw material costs. The price of plastic resins depends on global supply chain dynamics, petroleum costs, and demand fluctuations. To mitigate these risks, many manufacturers diversify their supplier networks and explore alternative materials.

Competition from Global Manufacturers

Arizona’s injection molding companies compete with manufacturers in regions with lower labor and production costs, such as China and Mexico. To stay competitive, Arizona-based companies focus on high-precision molding, quick turnaround times, and customized solutions that differentiate them from mass-production facilities overseas.

Labor Shortages and Workforce Development

The demand for skilled labor in the injection molding industry continues to grow, posing a challenge for manufacturers in Arizona. Many companies are addressing this issue by investing in employee training programs and collaborating with technical schools and universities to cultivate a new generation of skilled workers.

The Future of Injection Molding in Arizona

Adoption of Smart Manufacturing and Automation

Arizona’s injection molding industry is embracing smart manufacturing technologies, including robotics, real-time monitoring, and AI-driven quality control. These advancements improve efficiency, reduce waste, and enhance precision in the manufacturing process. Companies that integrate automation and digitalization into their operations will remain at the forefront of the industry.

Growth of Sustainable Manufacturing Practices

Sustainability is expected to play a significant role in the future of injection molding in Arizona. Manufacturers are investing in eco-friendly materials, energy-efficient equipment, and recycling initiatives to align with global environmental goals. The transition to greener production methods will not only benefit the environment but also improve cost savings and regulatory compliance.

Expansion of Customization and High-Mix, Low-Volume Production

With increasing demand for specialized plastic components, Arizona’s injection molding companies are expanding their capabilities in custom and low-volume production. Advanced mold-making techniques and flexible manufacturing processes allow businesses to produce unique, high-precision parts tailored to specific applications.

Injection molding companies in Arizona are well-positioned to serve a variety of industries with high-quality plastic components. The state’s strong industrial base, skilled workforce, and commitment to innovation make it a top destination for businesses seeking reliable plastic manufacturing solutions.

As the industry continues to evolve, Arizona-based injection molding companies are embracing advanced technologies, sustainable practices, and customized manufacturing solutions. With a focus on precision, efficiency, and adaptability, these companies are driving the future of plastic injection molding in the United States.

Expanding Injection Molding Capabilities in Arizona

The injection molding industry in Arizona continues to grow, driven by innovation, quality manufacturing, and evolving market demands. As companies seek to enhance their capabilities, many are investing in specialized techniques, high-performance materials, and state-of-the-art machinery to remain competitive in the industry.

With applications spanning across multiple sectors, injection molding companies in Arizona are focusing on providing precision, efficiency, and sustainability. Customization, automation, and advanced material science are shaping the future of plastic part manufacturing in the state.

Advanced Injection Molding Techniques Used in Arizona

Precision Molding for High-Performance Applications

Precision injection molding is essential for industries that require intricate and dimensionally accurate plastic components. Arizona-based manufacturers utilize computer-controlled molding machines, real-time monitoring systems, and high-tolerance tooling to ensure consistent part quality.

Industries such as aerospace, medical, and electronics rely on precision molding for components that must meet stringent performance and safety standards. The use of micro-molding and advanced quality control techniques helps injection molding companies produce defect-free, high-precision parts.

Multi-Shot and Overmolding Capabilities

Many injection molding companies in Arizona are expanding their services to include multi-shot molding and overmolding. These techniques allow manufacturers to mold different materials or colors within a single process, improving product functionality and aesthetics.

Overmolding is particularly beneficial for creating parts with soft-touch surfaces, enhanced durability, or additional grip. This process is widely used in medical devices, automotive components, and consumer products. By integrating multiple materials into one part, companies can eliminate secondary assembly operations and improve product reliability.

Insert Molding for Reinforced Plastic Components

Insert molding is another advanced technique used by injection molding companies in Arizona. This process involves encapsulating metal or other reinforcing materials within plastic, resulting in hybrid components that offer both strength and lightweight properties.

Common applications of insert molding include threaded fasteners, electrical connectors, and structural supports. By combining metal and plastic in a single manufacturing step, companies can produce high-performance parts with reduced assembly time and improved mechanical properties.

Material Selection for Injection Molding in Arizona

High-Performance Plastics for Demanding Applications

Material selection plays a critical role in the injection molding process, as different industries require specialized properties such as heat resistance, chemical stability, and impact strength. Injection molding companies in Arizona offer a variety of plastic resins, including:

- Polycarbonate (PC) – Used for impact-resistant parts such as automotive lenses and protective enclosures.

- Acrylonitrile Butadiene Styrene (ABS) – Commonly used in electronics, automotive components, and consumer goods.

- Polyethylene (PE) and Polypropylene (PP) – Lightweight and cost-effective materials for packaging and disposable products.

- Nylon (PA) – A durable material used in gears, bearings, and mechanical components.

- Polyetheretherketone (PEEK) – A high-performance polymer suitable for aerospace, medical, and industrial applications.

Arizona-based manufacturers work closely with clients to determine the best material for their products, ensuring optimal performance and cost-effectiveness.

Biodegradable and Recycled Plastics for Sustainability

Sustainability is a growing focus for injection molding companies in Arizona. Many manufacturers are incorporating biodegradable and recycled plastics into their production processes to reduce environmental impact.

Biodegradable polymers such as polylactic acid (PLA) and polyhydroxyalkanoates (PHA) are gaining popularity for eco-friendly applications. Additionally, recycled plastics are being used to create sustainable packaging, automotive parts, and construction materials.

By adopting green manufacturing practices, Arizona’s injection molding companies are meeting the increasing demand for environmentally responsible products while reducing production waste and energy consumption.

Custom Injection Molding Services in Arizona

Prototype Development and Low-Volume Production

Injection molding companies in Arizona offer prototyping services to help businesses develop and test new product designs before full-scale production. Rapid prototyping techniques, including 3D printing and soft tooling, allow manufacturers to create functional prototypes quickly and cost-effectively.

Low-volume production is another valuable service provided by Arizona-based injection molding companies. This is ideal for startups, specialized applications, and industries that require limited production runs. By offering flexible manufacturing solutions, companies can meet diverse customer needs while minimizing upfront costs.

Secondary Operations and Value-Added Services

Many injection molding companies in Arizona go beyond basic molding by offering secondary operations such as:

- Assembly and packaging – Providing finished products ready for distribution.

- Ultrasonic welding – Joining plastic components without adhesives or fasteners.

- Pad printing and laser engraving – Customizing parts with logos, serial numbers, and other markings.

- Surface finishing – Including polishing, texturing, and painting for enhanced aesthetics.

These value-added services enable businesses to streamline their supply chains by obtaining fully finished products from a single manufacturer.

Challenges and Opportunities for Injection Molding in Arizona

Supply Chain Management and Material Availability

One of the biggest challenges for injection molding companies in Arizona is navigating supply chain disruptions. The availability and pricing of raw materials, especially high-performance plastics, can fluctuate due to global demand and economic conditions.

To mitigate supply chain risks, manufacturers are diversifying their supplier networks, investing in local material sourcing, and optimizing inventory management systems. These strategies help ensure consistent production and minimize delays.

Investment in Automation and Smart Manufacturing

Automation is transforming the injection molding industry, allowing companies to increase efficiency, reduce labor costs, and improve product quality. Arizona-based manufacturers are integrating robotics, AI-driven quality control, and real-time data analytics into their production lines.

Smart manufacturing technologies enhance precision, detect defects early in the process, and optimize production workflows. Companies that invest in automation will gain a competitive edge in meeting high-volume and high-quality production demands.

Expanding Market Demand for Custom Plastic Components

The demand for custom injection-molded plastic parts is on the rise across various industries. Businesses seek tailor-made plastic components for applications ranging from medical devices to industrial machinery.

Injection molding companies in Arizona are capitalizing on this trend by offering highly customizable solutions, including specialized molds, unique color formulations, and multi-component molding. The ability to provide bespoke plastic mold designs allows manufacturers to serve a wide range of industries effectively.

The Future of Injection Molding in Arizona

Growth of Medical and Aerospace Manufacturing

Arizona’s medical and aerospace sectors are expected to drive further growth in the injection molding industry. As these industries continue to expand, the need for precision-molded plastic components will increase.

Medical injection molding requires stringent quality control, biocompatible materials, and cleanroom manufacturing conditions. Similarly, aerospace manufacturers demand lightweight, high-strength plastic components that meet rigorous safety and performance standards.

Integration of Sustainable and Energy-Efficient Practices

Sustainability will continue to shape the future of injection molding in Arizona. Companies are investing in energy-efficient molding machines, waste reduction strategies, and environmentally friendly materials.

By adopting sustainable manufacturing practices, Arizona’s injection molding industry can reduce costs, comply with regulatory requirements, and appeal to environmentally conscious consumers.

Expansion of Digital Manufacturing and Industry 4.0

The future of injection molding in Arizona will be heavily influenced by digital manufacturing technologies. Industry 4.0 solutions, including cloud-based production monitoring, AI-driven defect detection, and predictive maintenance, will enhance efficiency and production capabilities.

Manufacturers that embrace digital transformation will benefit from increased operational transparency, reduced downtime, and improved quality control. These advancements will position Arizona as a leader in high-tech injection molding.

Conclusion

Injection molding companies in Arizona are at the forefront of innovation, leveraging advanced technologies, sustainable practices, and customized solutions to meet evolving industry demands. The state’s strong industrial base, skilled workforce, and business-friendly environment make it an attractive location for injection molding manufacturers.

By investing in automation, precision engineering, and eco-friendly production, Arizona-based companies are well-positioned for future growth. As the industry continues to evolve, the integration of smart manufacturing, material advancements, and high-quality plastic mold solutions will drive success in the injection molding sector.